Wire Forming: What Is It? How Does It Work? Types & Uses

By A Mystery Man Writer

Multi-chapter guide to Wire Forming describing: what is a wire forming, how wire forming is done, types of wire forming, how wire formed wires are used.

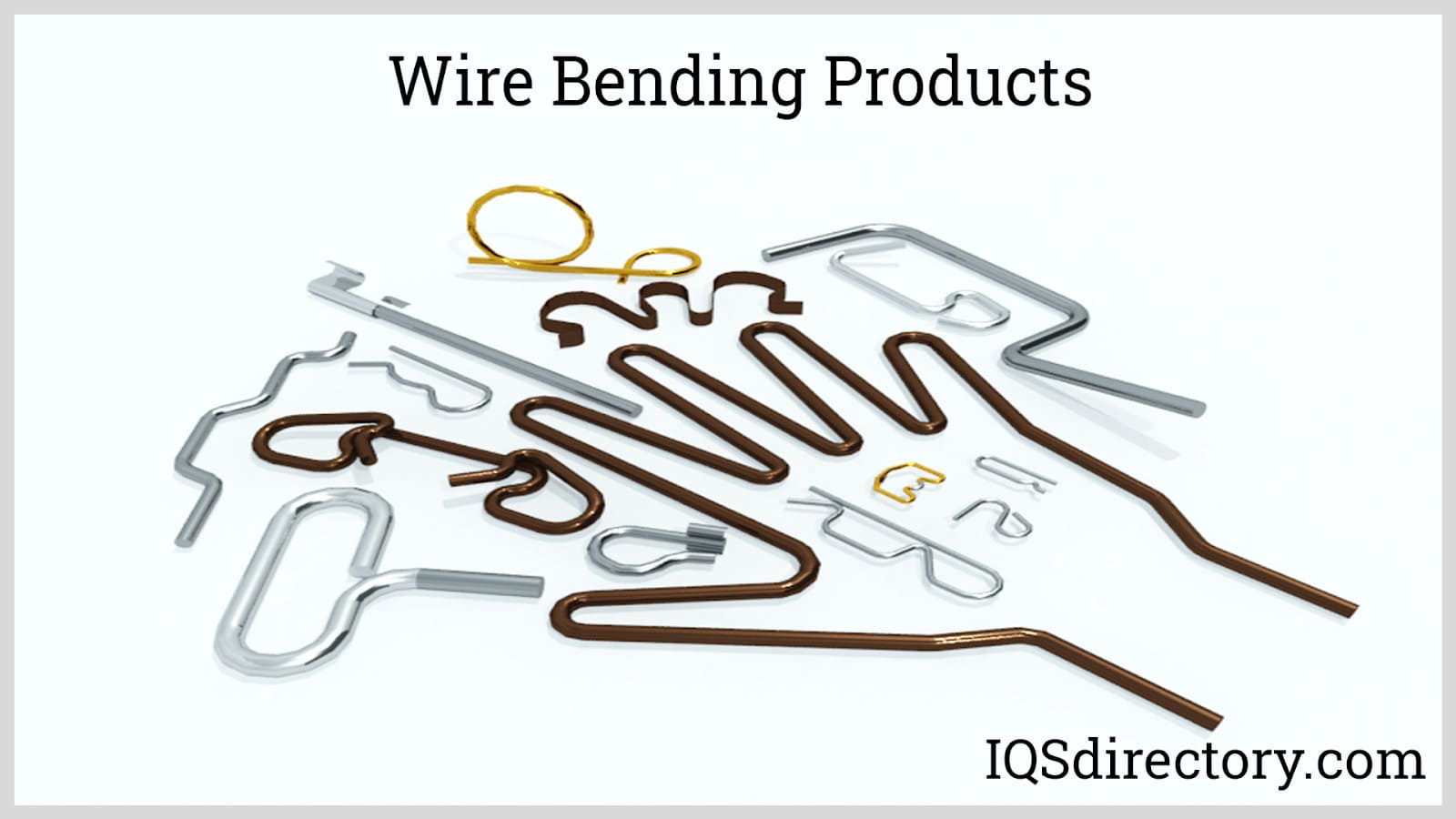

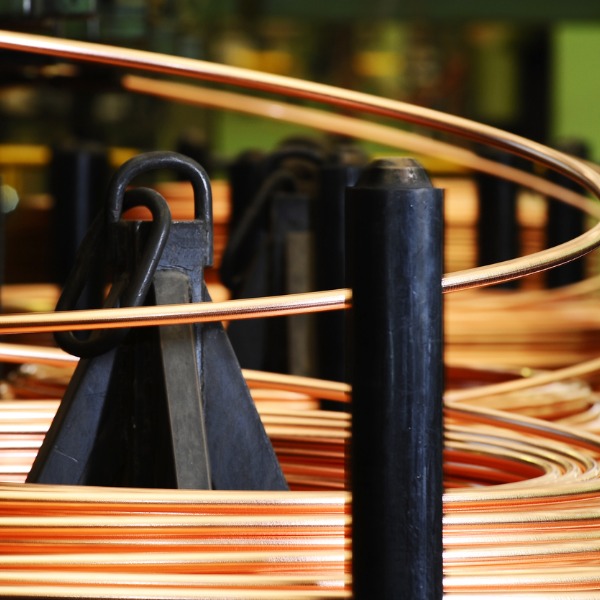

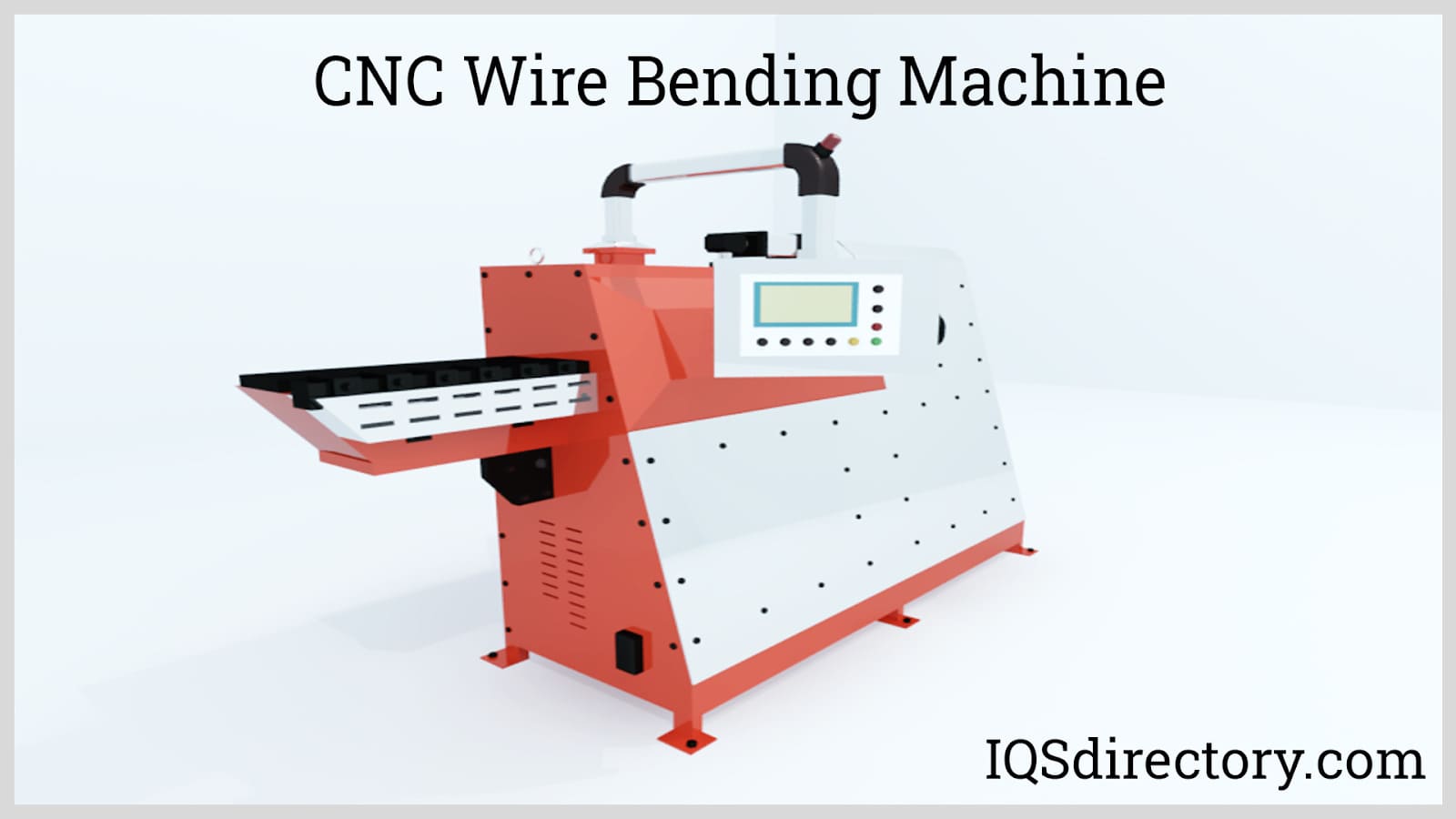

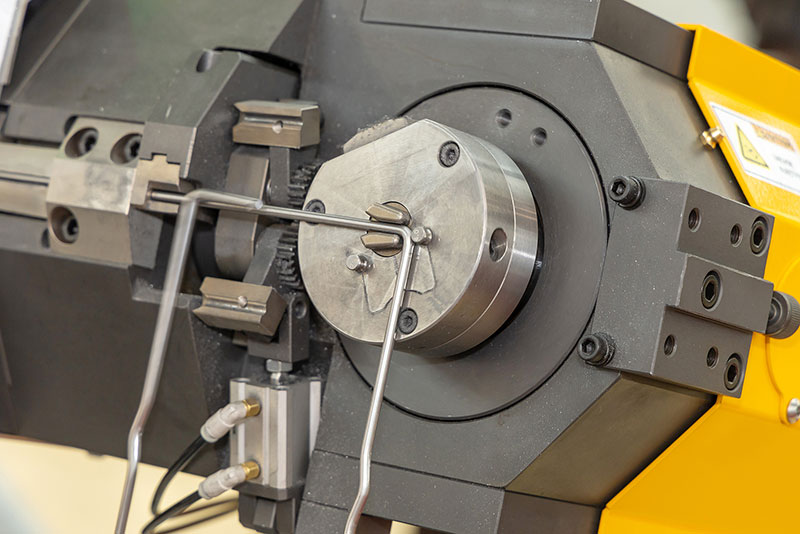

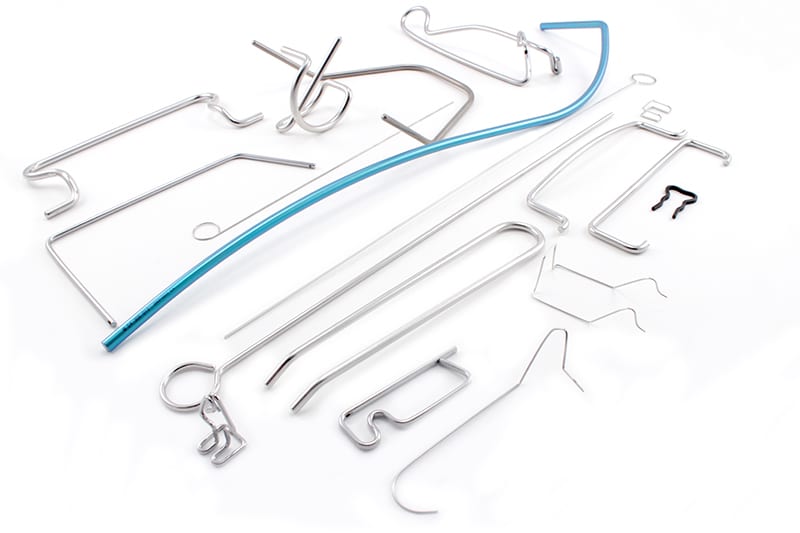

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration. The process starts with coiled wire that is straightened before being formed. Common metals used for wire forming include steel, brass, stainless steel, copper, aluminum, and a variety of different alloys. The diameters of wires vary from 0.5 mm to 6.5 mm, or 1/64th of an inch to a quarter inch and can produce 2 and 3 dimensional wire forms. The types of equipment to complete wire forming vary between manual crafting to advanced CNC programmable machines. The process includes options for coating and protecting final products for use in harsh conditions.

Exploring the Different Types of Wire Form Manufacturing Processes - Acme Wire Products - Medium

Why Wires? Let's Talk Science

Network cable connectors come in many forms for different networks by networkpatchpanel - Issuu

Custom Wire Forms, Wireform Prototyping

Wire Forming: What Is It? How Does It Work? Types & Uses

:max_bytes(150000):strip_icc()/nonmetallic-cable-sheathing-color-1152905-final2-c48c6eee82ab43b9ad6c15bbc473c839.jpg)

Color Coding of Nonmetallic (NM) Electrical Cable

Cable, Types, Uses & Benefits

Wire Forming: A Comprehensive Guide - Clark Engineering

Electrical cable - Wikipedia

How Wire Forming Machines Work - Flip eBook Pages 1-3

Wire Working and Wire Forming, Reid Wire

Wire Forming: What Is It? How Does It Work? Types & Uses

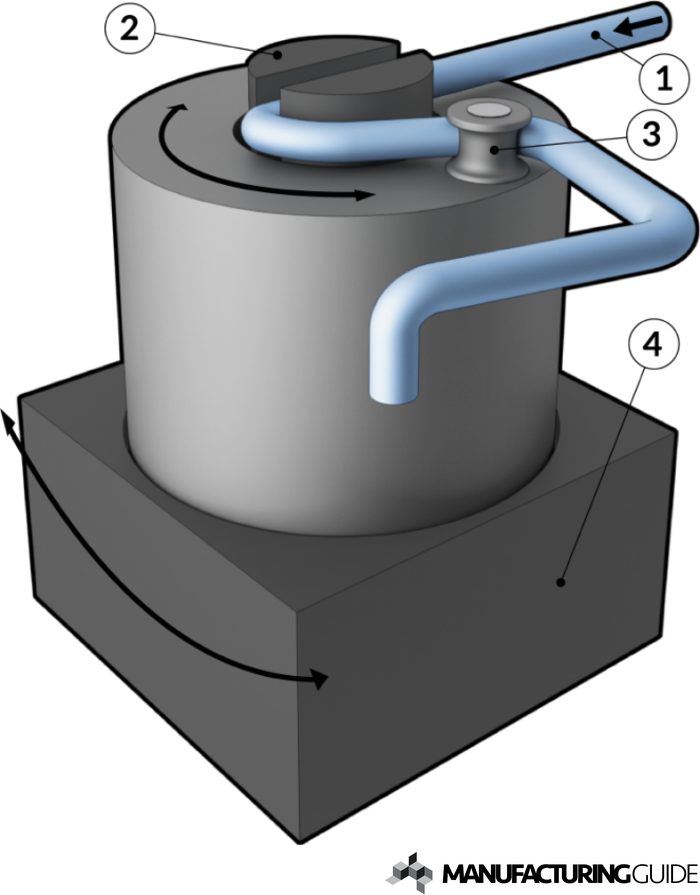

Wire Forming Methods Used for Wire Forming

Cable-stayed bridge, Definition & Facts

Wire Forms Basics - Fabrication, Applications & Materials

- Tommy Hilfiger Women's Layered-Look V-Neck Sweater - Macy's

- De Para Zapatos Mujer Moda Tenis Zapatillas Correr Transpirables Tennis New 2023

- Toddler Underpants 2t Kids Toddler Girls Cotton Underpants Letter Print Underwear Shorts Pants Girl Size 5 : : Clothing, Shoes & Accessories

- Buy Shadow Gray Silk Dual Shade One Minute Saree With Belt

- KappAhl, Ekoligens AB develop sustainable hangers